Water research can result in a lot of plastic waste. High-quality sample collection — such as that for researching emerging contaminants like perfluoroalkyl and polyfluoroalkyl substances (PFAS) — requires sterilized containers that, unfortunately, can’t be reused or even recycled in most cases.

Is there an economical and efficient way to reduce the waste?

Product engineers at Whirl-Pak, Filtration Group, a Wisconsin-based company that makes secure sampling bags, think there is, and they’ve tapped students and faculty at UW Oshkosh to help.

Whirl-Pak is well-known in the dairy industry, having developed a process called the universal sampling procedure to help ensure milk quality. The company branched into the water industry in 1981 and has seen significant success in the United Kingdom with replacing conventional rigid sampling bottles with their flexible bags, which require less plastic, water and emissions to produce and ship. To grow their business in the United States, they wanted to identify a lab that was processing large quantities of water samples.

When a company representative asked the Freshwater Collaborative of Wisconsin for help, Marissa Jablonski, executive director, immediately thought of UW Oshkosh’s Environmental Research and Innovation Center (ERIC). The state-certified laboratory hires students to provide well water testing and bacteriological and chemical analysis for water systems.

The connection has resulted in a university-industry partnership that provides valuable work experience for students, helps solve a business challenge and may reduce plastic pollution. It’s a win-win-win project that exemplifies how academia and industry can work together.

Their efforts are being supported by the Water Enterprise Program at UW Oshkosh, which connects university researchers and students with industry partners to address issues important to those partners. The program is part of the suite of projects at UW Oshkosh funded by the Freshwater Collaborative. It allows faculty and academic staff to request a mini grant (up to $15,000) to work on an innovative project with an external partner. The projects must also include student researchers.

Carmen Ebert, associate lab director for ERIC lab, submitted a request in 2022 to conduct initial research and development on Whirl-Pak products.

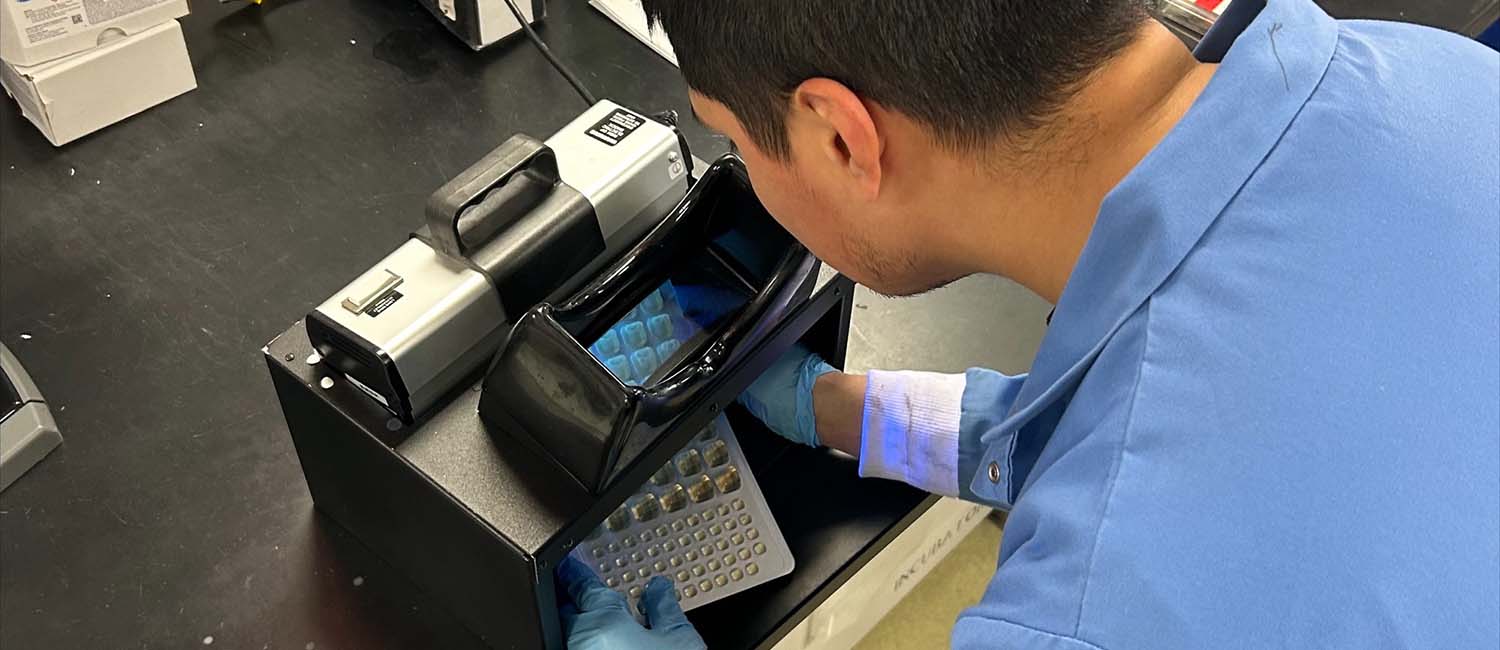

“This was an opportunity to jumpstart the project with Whirl-Pak,” she says. “We looked at the feasibility of using their bags for collection as well as incubation of samples in the lab. We then inoculated the bags with known organisms and compared the bags to known methods of collection.”

Once they proved Whirl-Pak bags could be used to sample effectively and that samplers liked using them, Cherelle Bishop, Whirl-Pak’s product engineering manager, wanted to develop a more targeted case study. Bishop wants to gather data to show potential customers that their sampling bags work just as well as conventional containers — and have the added benefits of reducing plastic waste and the storage space required for collection containers.

She and Ebert received a second mini grant from the Water Enterprise Program in 2023 to conduct more in-depth testing of the bags and their ability to sample surface and well water. Students conduct the lab testing and analysis under the guidance of ERIC staff. Erick Carranza, a UW Oshkosh graduate student, says working on the project has increased his familiarity with methods of detecting bacteria.

“My favorite part of this project has been being exposed to a new form of detection for coliform bacteria and E. coli,” he says. “I had never used the standard method of detection prior to working at the ERIC lab, and now learning the Whirl-Pak method for the same purpose is exciting.”

The partnership goes beyond R&D. Last year, Bishop was invited to the Great Lakes Beach Association Conference, which was hosted by UW Oshkosh, and the Freshwater Collaborative’s FresH2O Partner event. Both events provided her with opportunities to meet more people working in the water sector and learn what’s important to them. She also visited UW Oshkosh to meet students and see firsthand some of the other research taking place. She sees the partnership as mutually beneficial.

“UW Oshkosh is a Wisconsin-based university and we’re a Wisconsin-based company. We want stronger ties with the UW System,” she says. “We wanted to craft something that was exciting for both of us. There’s engagement and momentum and that can only bring good things to both sides.”